Our Tools

DRP uses advanced equipment and techniques for the preparation of samples for both optical and electron microscopy.

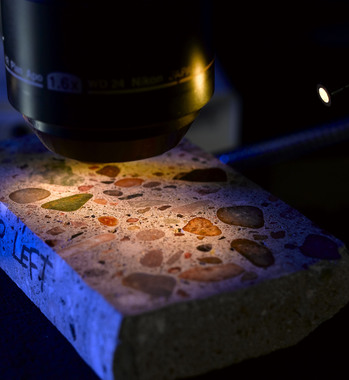

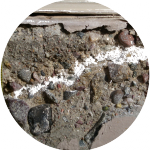

Stereomicroscopic examinations of polished slabs allow for detailed examination of the full thickness of a construction element.

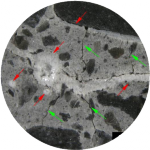

Petrographic thin sections facilitate studies of paste microstructure and secondary reaction mechanisms such as sulfate attack and alkali-silica reaction.

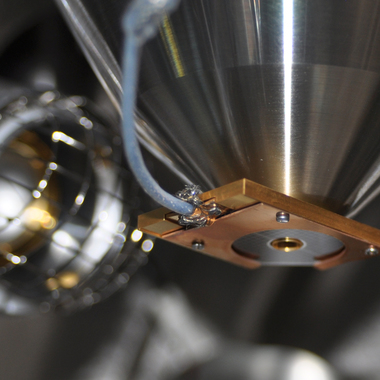

Good things come in small packages. This little wafer is the backscatter electron detector for the scanning electron microscope.

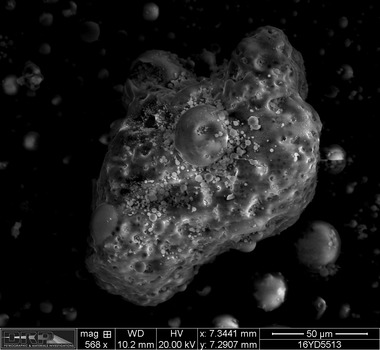

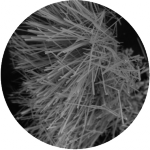

The electron microscope is a powerful tool for characterizing raw materials, such as this fly ash particle.

The most important tool in petrography is understanding how to relate microstructural observations to the performance of the material in the larger structure.

An Unwavering Focus on Petrography

We made a deliberate choice to focus on our energy on what we do best: petrographic analysis. We use state-of-the-art equipment and techniques to unlock the microstructure of construction materials.

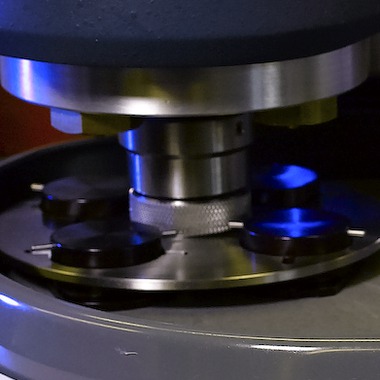

Optical Microscopy

Electron Microscopy

Condition Surveys

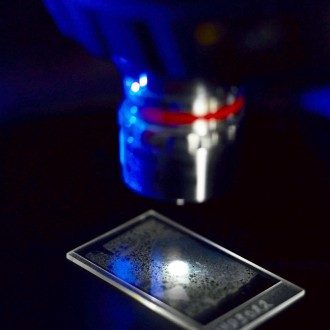

Fluorescence Microscopy

Electrical Resistivity

Questions? We have answers. Contact us.

Give us a call at 303.938.0166 to get your project rolling.