Materials

DRP has extensive experience in using petrography to provide quality assurance and to troubleshoot materials issues. Our quality assurance services most commonly involve petrographic analysis of aggregates (ASTM C295), microscopical analysis of air void systems in hardened concrete (ASTM C457) and petrographic analysis of precast concrete products such as railroad ties (ASTM C856). We also help clients troubleshoot materials issues that can crop up during or soon after construction, such as low strength and early age cracking.

You have to love them. Granitic aggregate fresh from the Colorado Front Range.

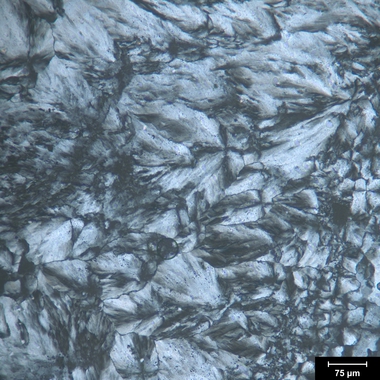

Cross-polarized transmitted light photomicrograph of thin section of chalcedonic chert, which is often highly susceptible to ASR.

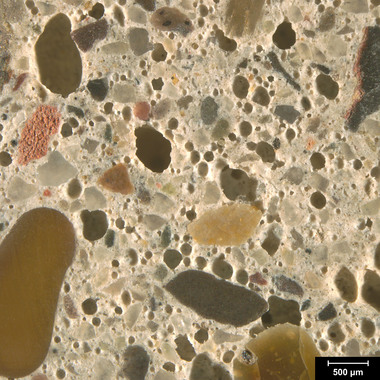

Oblique reflected light photomicrograph of polished surface showing showing concrete with excessive air (16%).

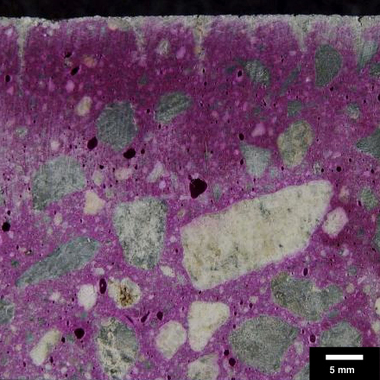

Photograph of phenolphthalein-stained slab showing plastic shrinkage cracks.

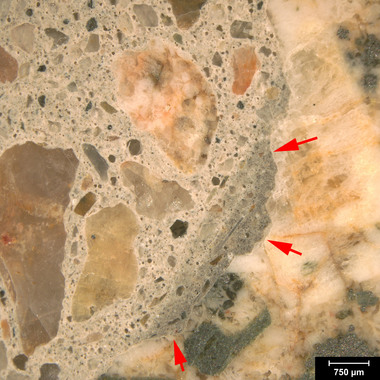

Reflected light photomicrograph of low w/cm mortar coatings (red arrows) on an aggregate particle. Such coatings are typical of late water additions, or retempering, which can diminish strength.

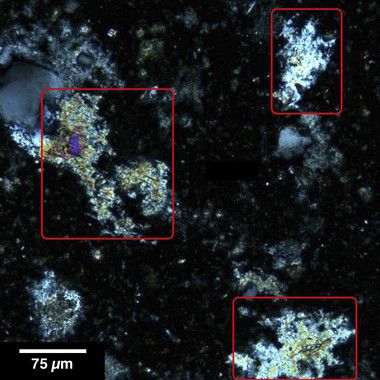

Cross-polarized transmitted light photomicrograph showing coarse portlandite crystals (red boxes) in low-strength concrete which had a high w/c.

Questions? We have answers. Contact us.

Give us a call at 303.938.0166 to get your project rolling.